The compaction factor test of concrete is conducted to determine the workability of concrete. Normally we use slump test on the construction site but it does not give accurate results for the low workability of concrete when the slump is less than 50mm.

Recommended Slump values for different Structures are given in the below table. We can use low workable concrete for Rcc beam & slab, Pavements, Rcc Foundation & wall, Bridge & Flyover dec, Footing without reinforcement.

| Sr. No | Structure Type | Min. Slump Value (mm) | Max. Slump Value (mm) |

| 1 | Columns | 75 | 125 |

| 2 | Rcc beam & slab | 30 | 125 |

| 3 | Pavements | 25 | 50 |

| 4 | Rcc Foundation & wall | 50 | 100 |

| 5 | Rcc Wall | 50 | 100 |

| 6 | Bridge & Flyover deck | 25 | 75 |

| 7 | Footing without reinforcement | 25 | 75 |

The ratio of the weight of partially compacted concrete to the weight of fully compacted concrete is known as the compaction factor. The Compaction factor of concrete varies from 0.7 to 0.95.

Table of Contents

Role of Low Workable Concrete:

Low workable concrete reduces thermal stress. Low slump value minimizes the chances of concrete bleeding. It is used in Mass concreting foundations and lightly reinforced sections. In this type of concrete desired workability is obtained with the help of admixtures.

Compaction Factor Test Apparatus:

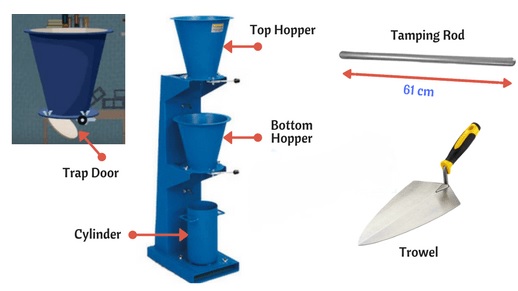

The compaction factor test apparatus comprises two conical hoppers and a bottom cylinder which is arranged as shown in the below image. A steel rod of 1.6cm diameter with a length of 61cm is utilized to tamp the mixed concrete and a weight balance is used to measure the weight of mixed concrete.

Compaction Factor Test Procedure:

Here is the step-by-step procedure of the compaction factor test of concrete.

- Take the sample of M20 grade concrete.

- Prepare the mix with 1:1.5:3 by adding the suitable quantity of water as per the Water cement ratio. Now mix the wet and fresh concrete.

- Make sure that the Inner surfaces of conical hoppers should be free from moisture and apply grease to it. Close the trap door of the upper hopper.

- Now measure the weight of the empty bottom cylinder and consider it as W1.

- Fill the freshly mixed concrete into the upper conical hopper using a trowel without compacting it.

- Next, the trap door of an upper hopper is opened. Hence, the concrete falls on the lower hopper.

- Wait for 2-3 secs and check whether the entire concrete is fallen from the upper hopper to the bottom hopper. If not, slight tamping is done until the whole concrete falls to the bottom hopper.

- Now open the bottom hopper trap door, and the entire concrete is fallen to the cylinder. Cut off the excess quantity of concrete on the top surface of a cylinder using the trowel.

- Measure the Weight of the cylinder with partially filled concrete and consider it as W2.

- Then the cylinder is vacant, and the concrete sample is filled again by filling it into 3 layers each layer is compacted by giving 25 blows using the tamping rod. Now, the concrete inside the cylinder is fully compacted.

- Determine the weight of the cylinder with fully compacted concrete and consider it as W3.

Compaction Factor Test Formula:-

If you find my article on “compaction factor test of concrete” useful, please let me know.

Keep supporting us by reading my articles.