Table of Contents

Culvert Definition:

A culvert is a structure, usually made of concrete or metal, that is used to allow water to flow under a roadway, railroad, trail, or other obstruction.

Culvert Meaning:

The term “culvert” generally refers to a structure that is designed to allow water to flow under a roadway, railroad, trail, or other obstruction.

What Is Culvert?

Culvert is a small bridge having a total length of 6 meters or less than 6 meters between the faces of abutments.

Culvert is an everlasting drainage structure chiefly constructed to carry roadway or railway track over small streams or channels. Culvert can be constructed using a pipe, RCC, plain concrete, or other suitable materials.

Materials Used In The Construction Of Culvert

Large pipes known as culverts are used to allow water to flow underneath roads, railways, and other structures. They can make culverts from various materials like concrete, steel, plastic, aluminum, and high density polyethylene. Culvert constructors often prefer concrete due to its strength, durability, and resistance to erosion and weathering.

Culverts can be either reinforced or non-reinforced, and constructors can construct them on site or precast off site. In some cases, constructors can use a combination of materials to create composite culverts. Culverts made of steel and plastic are also common, while aluminum, being lightweight and easy to install, is popular for use in remote areas.

The choice of culvert material will depend on several factors, such as the expected loads, environmental conditions, and available budget for the project. It is important to consult a qualified professional to determine the most suitable material for a specific culvert construction project.

How To Select Location Of A Culvert

When determining the location of culverts, two main factors to consider are economy and usage. Culverts placed under roadways or railways are typically more cost-effective than constructing separate embankments.

To ensure maximum efficiency, culverts should be perpendicular to the roadway and have dimensions large enough to accommodate high water levels. Additionally, they should be placed in a manner that allows for easy water flow, which can be achieved through the use of appropriate gradients.

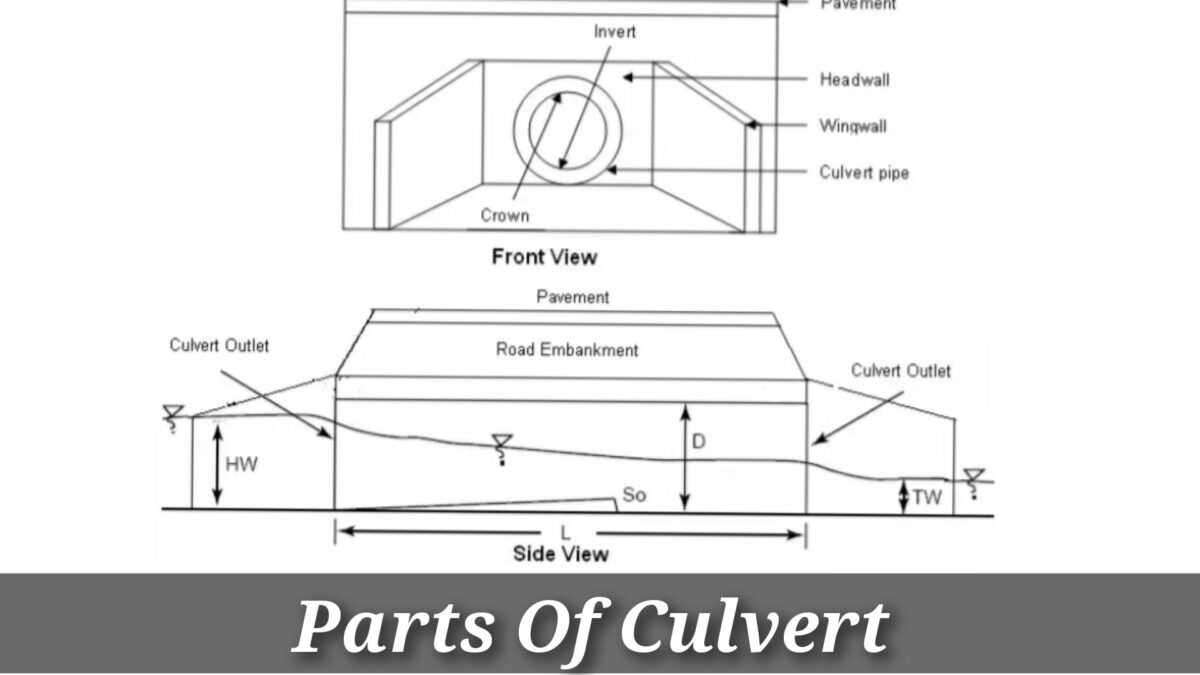

Components Of A Culvert

Culverts are made up of several parts, including:

- Inlet: The inlet is the opening of the culvert through which water enters. It can be either square, rectangular, or circular in shape.

- Outlet: The outlet is the end of the culvert from which water flows out. Like the inlet, it can be either square, rectangular, or circular in shape.

- Headwall: The headwall is a vertical structure that is used to retain the soil on either side of the culvert. It can be made from concrete or masonry.

- Wingwalls: Wingwalls are sloping structures that are used to channel water towards the culvert inlet. They are also used to prevent erosion of the soil around the inlet and outlet.

- Apron: The apron is a concrete slab that is placed at the outlet of the culvert to prevent erosion and scour.

- Culvert Barrel: The culvert barrel is the section of the culvert that runs between the inlet and outlet. It can be made from various materials such as concrete, steel, or plastic.

- Footing: The footing is a foundation that is used to support the weight of the culvert. It can be made from concrete or masonry.

- Bedding: The bedding is a layer of material that is placed beneath the culvert barrel to provide support and prevent settling.

- Backfill: Backfill is the soil that is placed around the culvert after it is installed. It is used to fill the voids around the culvert and provide support.

Each part of a culvert plays a critical role in ensuring the proper flow of water and the stability of the roadway or railway above it.

Types Of Culvert

There are four types of the culvert as follows:

- Arch Culvert.

- Open or Slab Culvert.

- Pipe Culvert.

- Box Culvert.

1. Arch Culvert:

The culvert having its superstructure comprises one or two arches constructed of any suitable masonry is known as an arch culvert.

In these culverts, segmental arches comprised of brick masonry, stone masonry, or concrete are commonly used. These types of arches can be easily and cheaply constructed. The abutments and piers or these arches are constructed sufficiently strong to take their lateral thrust Arch culverts are particularly suitable where the approaches are to be constructed in cutting.

2. Slab Culverts:

The culvert, having its superstructure comprises of an RCC slab that carries the bridge floor, is known as a slab culvert.

In this type of culvert, the RCC slab of suitable thickness serves as simply supported over abutments and piers which are constructed of any appropriate type of masonry. Slab culverts are appropriate where the bed of the canal or stream is sufficiently firm. These are provided up to the maximum span of 3 m.

3. Pipe Culvert:

The culvert which comprises of one or more pipes placed side by side over a concrete base below the embankment of a roadway or railway track is called a pipe culvert.

In this type of culvert, one or more pipes comprised of cast iron, steel, or RCC are held in position over a concrete base by fixing both ends into masonry walls. In pipe culverts, mostly, more than one pipe, of diameter not less than 30 cm is used. Nonetheless, their exact number and diameter are based upon the discharge and height of the bank. As far as possible the gradient of the pipe should not be less than 1 in 1000. Pipe culverts are desirable where the flow of water in the stream is very small.

4. Box Culvert:

The culvert comprises one or more numbers of rectangular or square openings, having their floor and top slabs constructed monolithically with abutments and pier, which is called a box culvert.

Box culvert is normally constructed of precast RCC slabs. Small span box culverts may be built of stone slabs, supported on masonry abutments, with brick or stone flooring. These culverts provide the least intervention to traffic during construction.

Box culverts are primarily constructed where the soil is soft and the load has to be distributed over a wider foundation area. This type of culvert can be conventionally utilized for a single span of 3 m or for a double span of 6 m.

Advantages:

- Culverts offer a cost-effective solution for managing water flow, as they cost less than bridges.

- Installing culverts is easy and quick, reducing construction time and costs.

- Culverts require minimal maintenance once installed, reducing long-term maintenance costs.

- Culverts can be designed and constructed to suit different site conditions, such as varying soil types and water flow rates.

- Culverts reduce erosion by managing water flow and slowing down the speed and force of water runoff.

- Culverts provide safe passage for wildlife, such as fish and amphibians, across roads and other infrastructure.

- Culverts help to reduce the risk of flooding by managing water flow and preventing the accumulation of water in low-lying areas.

- Culverts increase safety by reducing the risk of accidents caused by standing water on roads and other infrastructure.

- Culverts improve drainage in areas where water tends to accumulate, reducing the risk of water damage to nearby structures.

- Installing culverts causes minimal disruption to traffic and other activities, reducing the impact on nearby communities and businesses.

Disadvantages:

- Culverts have a limited capacity and may not be suitable for managing large volumes of water.

- Culverts have a limited lifespan and may require replacement or repair after a certain period of time.

- Culverts can become blocked by debris, causing water to back up and potentially flood nearby areas.

- Culverts can be damaged by heavy equipment or vehicles, resulting in costly repairs.

- Culverts can negatively impact the environment by altering natural water flow patterns and disrupting habitats for wildlife.