Kelly ball test is used to measure concrete workability. It is also known as a ball penetration test.

Kelly ball test was developed in USA by a person named Kelly.

This test is a simple field test that is extremely useful to measure the workability and consistency of freshly mixed concrete. It is advocated that the Kelly ball test performed quicker and gave exact results with great accuracy than the concrete slump test. Yet, the lone hindrance with the Kelly ball test is that it needs a large amount of concrete when compared with the slump cone test of concrete.

Table of Contents

Apparatus of Kelly Ball Test

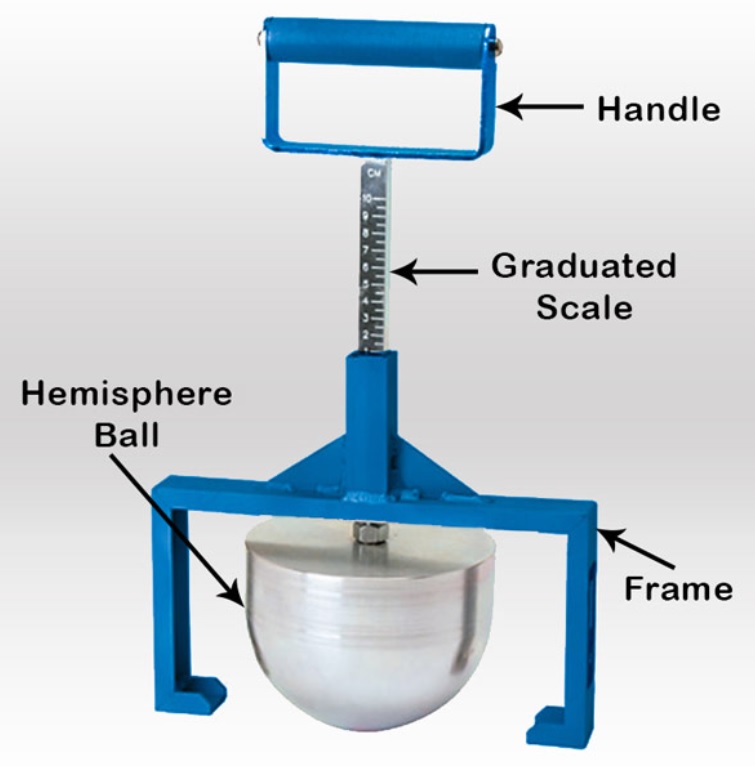

As you can see in the figure, it consists of a metal ball, graduated scale, and handle. All of these arrangements are fixed with a stand.

The flat end of this hemispherical ball is attached to the frame as shown in the figure. The results have been determined by estimating the penetration made by the hemisphere when freely placed on wet and fresh concrete. The impression is estimated by a graduated scale right quickly.

Test Procedure of kelly ball test

- A good mass of concrete is needed.

- The surface of the concrete is struck off level.

- The ball is gradually measured on the surface.

- The depth of the penetration is recorded to the nearest 6 mm.

- At least 3 measures have to be made which are called Kelly ball penetration values.

- Calculate the average penetration values of all the readings.

Result

Concrete Workability = Average ball penetration value.

Advantages

- It gives very precise results.

- This test can perform quickly on a construction site.

Disadvantages

- If the concrete thickness is very thin or thinner than 20 cm, this test does not give any result.

- This test does not give accurate results if the size of the coarse aggregate is very large.

- It required a large amount of concrete to perform the test.