Non-threaded strong joints that are normally made of steel or aluminum of head and sank is known as Rivet.

Table of Contents

Riveted joints

Riveted joints are the joints that are perpetual, comprising of fundamentally two parts that are controlled together by the bolt, head at the top, and tail (barrel-shaped stem) at the base.

Types of Riveted Joints

- Lap Joint

- Butt Joint

1. Lap joint

As the name suggests, in this type of joint, two-member slightly overlap each other. These two members joined together through the coincident holes.

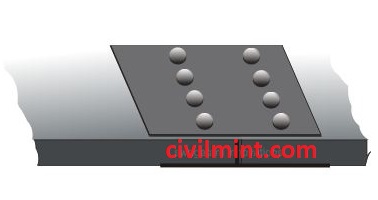

2. Butt Joint

In this type of joint straight edges of the members are joined by using the cover plate. Clamping is done by using this cover plate. ( as shown in the figure )

Advantages

- Less expensive manufacture cost.

- Low repairing cost.

- Different metals can likewise be joined, even non-metallic joints are conceivable with bolted joints.

- The simplicity of riveting interaction.

Disadvantages

- Talented laborers required.

- Spillage might be an issue for this kind of joint, yet this is overwhelmed by extraordinary strategies.

Applications of riveted joints:

- Kettle shells.

- Structures members and bridges members.

- Rail route carts and coaches.

- Transports and trucks.